| –

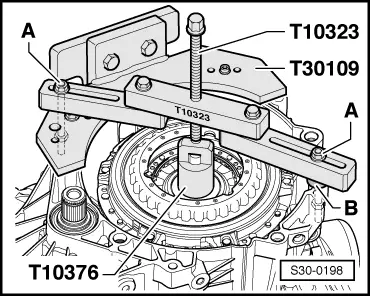

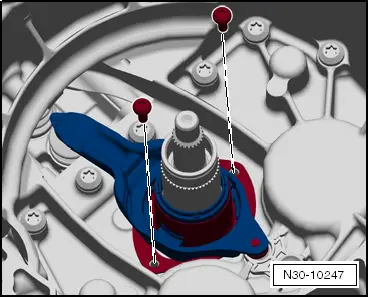

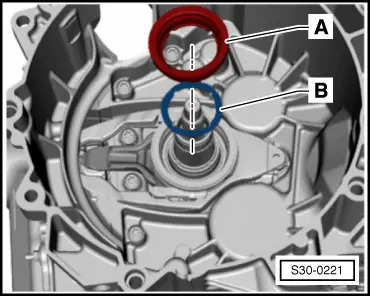

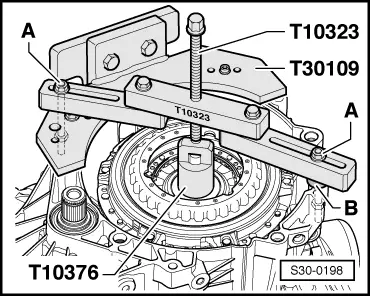

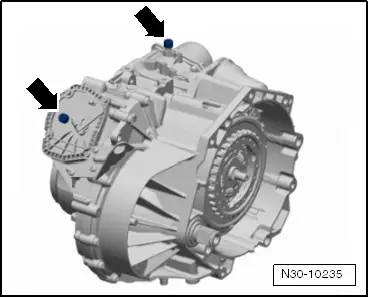

| Position the supporting bridge -T10323- parallel to the flange of the clutch housing. |

| –

| Equalise distances, e.g using washers -B- with a total thickness of 15 mm. |

| –

| Attach the supporting bridge -T10323- with screws -A-. |

Note | Fasten screws -A- with nuts. |

| –

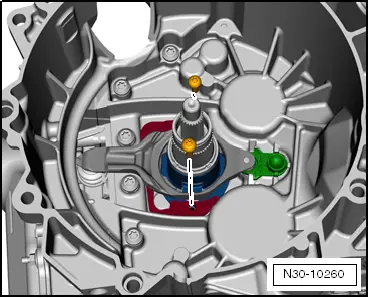

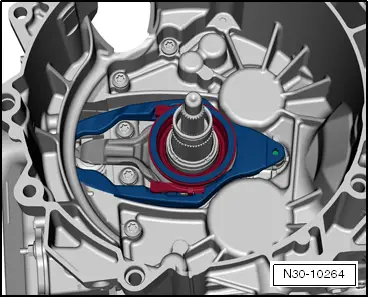

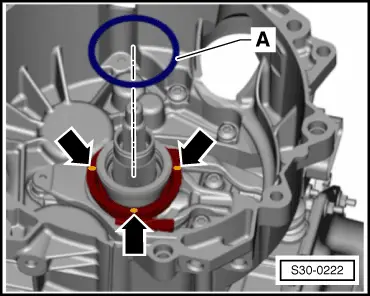

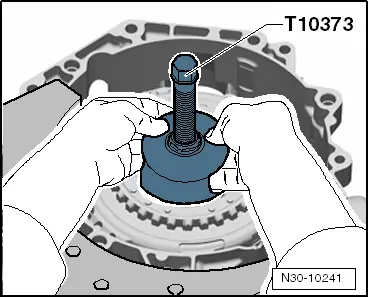

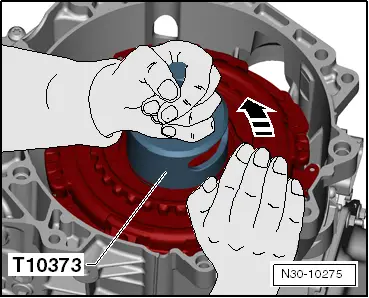

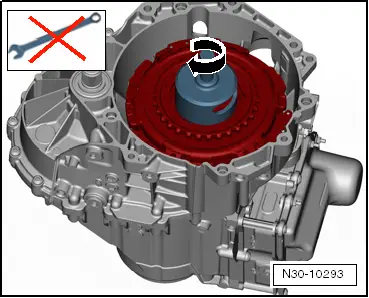

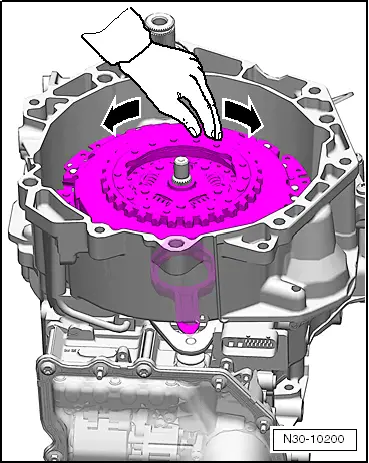

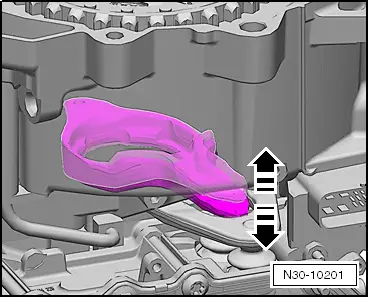

| Press the clutch downwards via the spindle. |

Note | t

| During press-in procedure, place a hand onto the clutch. A slight rattling can be felt. Rattling means that the clutch is pressed into its fitting position. In this way, it can be »detected« if the clutch is pressed in up to the stop. |

| t

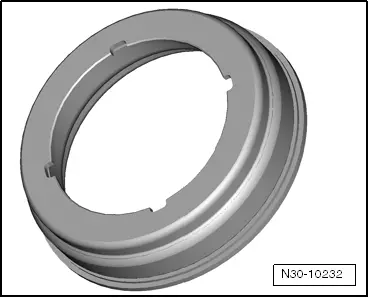

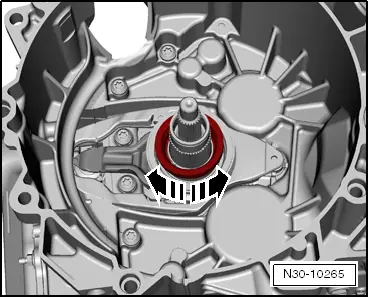

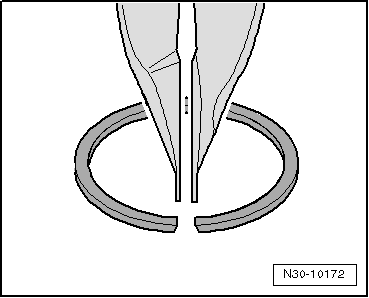

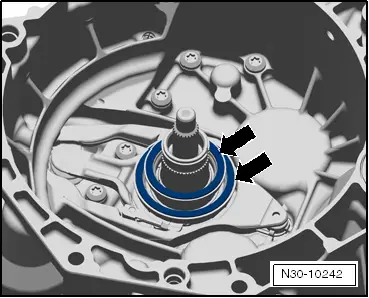

| The clutch is pressed in up to the stop if the circlip can be inserted. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Caution

Caution