| (Adjusting the differential gear) |

| Special tools and workshop equipment required |

| t

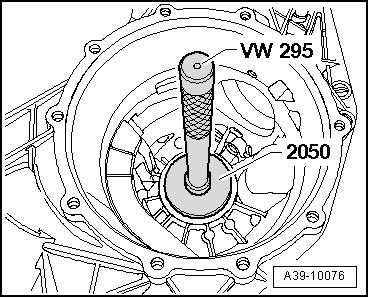

| Drift -MP3-403 (VW 295)- |

| t

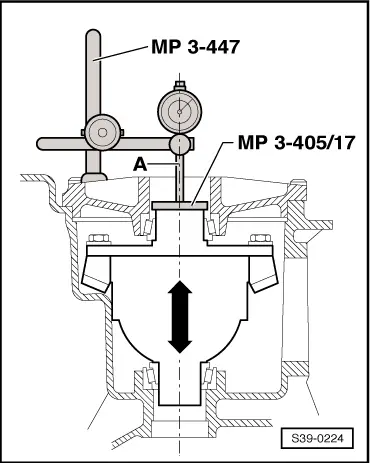

| Gauge block plate -MP3-405/17 (VW 385/17)- |

| t

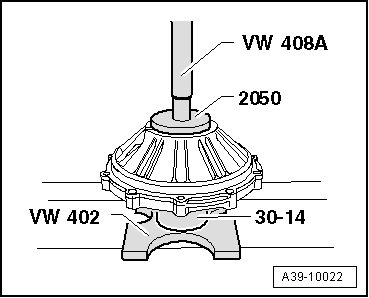

| Pressure plate -MP3-407 (VW 402)- |

| t

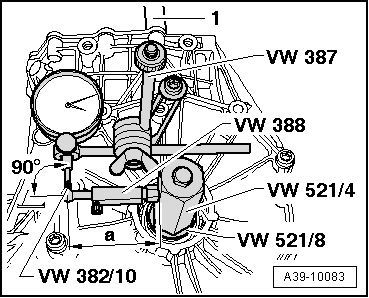

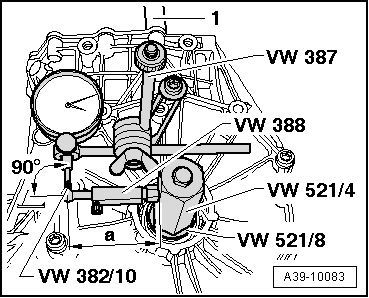

| Universal dial gauge holder -MP3-447 (VW 387)- |

| t

| Thrust piece -MP3-448 (VW 408A)- |

| t

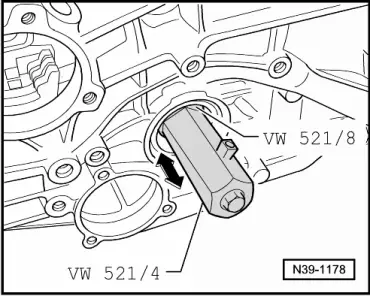

| Pipe section -MP3-462/4 (VW 521/4)- |

| t

| Bushing -MP3-462/8 (VW 521/8)- |

| t

| Pressure pipe -MP6-408 (30-14)- |

| t

| Dial gauge extension -VW 382/10- |

| t

| Gauge handle, adjustable -T30014 (VW 388)- |

| t

| Pressure plate -T30042 (2050)- |

| t

| Dial gauge extension 30 mm |

| The crown wheel must be re-set when the following components are replaced: |

| Gearbox housing, final drive cover, differential gear tapered roller bearings, differential gear housing, or drive train. |

| Determine overall washer thickness “Stot.” for the adjusting washers “S1” + “S2” |

| (Pre-load setting of tapered roller bearing for differential) |

| l

| Secondary shaft removed. |

| l

| If only the tapered roller bearing for differential was replaced, the crown wheel can be removed from the differential housing. The secondary shaft does not need to be removed. |

| –

| Removing the gasket rings for flange shafts. |

| –

| Remove outer rings/tapered roller bearing for differential and take out the adjusting washers → Chapter. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note Note

Note