|

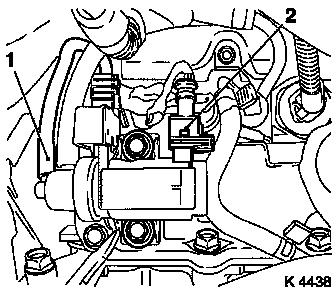

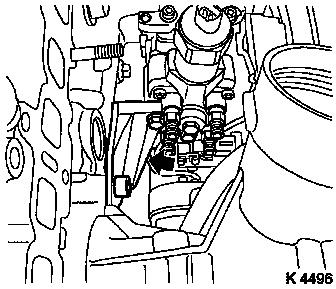

Adjust diesel fuel injection pump (Y 17 DTL,

without air conditioning, LHD)

| 1. |

Remove exhaust recirculation solenoid valve

| • |

Detach wiring harness plug (2).

|

|

|

|

| 2. |

Remove right rear engine transport shackle

|

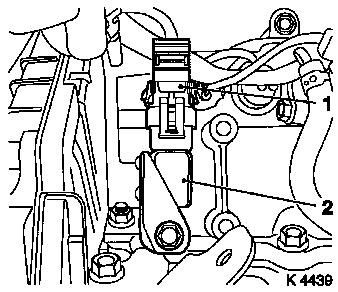

| 3. |

Remove charge pressure sensor (2)

| • |

Disconnect wiring harness plug (1)

|

|

|

|

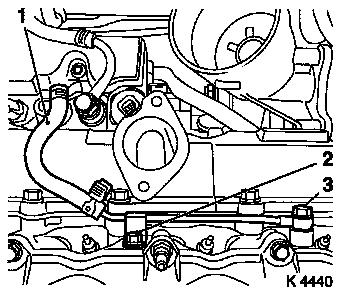

| 4. |

Detach outer oil leak line

| • |

Unscrew banjo bolt (3), bolt (2)

|

| • |

Remove oil leak hose (1)

|

|

|

|

| 5. |

Remove wiring harness plug

| • |

From diesel injection pump

|

|

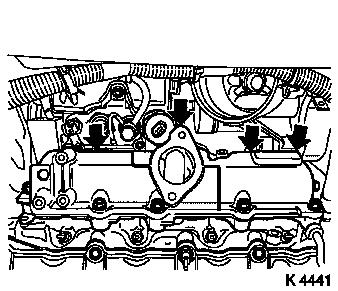

| 6. |

Remove two piece intake manifold

| • |

Unscrew 7 bolts, 2 nuts

|

|

|

|

| 7. |

Remove outer diesel injection pump insulation

|

| 8. |

Remove wiring harness for engine management

| • |

Disconnect wiring harness plug

|

|

| 9. |

Remove inner diesel injection pump insulation

Important: Prise off

carefully

|

| • |

2 off

|

|

| 10. |

Detach fuel injection pump bracket (arrow)

| • |

From injection pump

Note: Unscrew 2 bolts

by several turns

|

|

|

|

| 11. |

Adjust diesel injection pump

| • |

Turn crankshaft to 1st Cylinder TDC

Note: Pin on oil pump

cover must align with mark on torsional vibration damper.

|

| • |

Loosen diesel injection pump

|

| • |

Turn diesel injection pump until 0.33 mm adjustment value is

accomplished

| – |

Value too high - turn diesel injection pump toward engine

|

| – |

Value too low - turn diesel injection pump away from engine

|

|

| • |

Tighten diesel injection pump ( 19.6

Nm )

|

|

| 12. |

Check start of feed

| • |

Turn crankshaft approx. 675°

|

| • |

Install KM-798 under pre-tension

|

| • |

Determine BDC position of injection pump plunger by turning

crankshaft back and forth

Note: Dial gauge needle

must not move

|

| • |

Turn crankshaft to no.1 cylinder TDC

Note: Pin on oil pump

must align with mark on belt pulley,

|

Important: If test value is not

achieved, diesel injection pump setting must be repeated

|

| • |

Read test value

| – |

Test value: 0.28 – 0.38 mm

|

|

|

| 13. |

Remove KM-798

| • |

Tighten central bleeder screw ( 23.5

Nm )

|

|

| 14. |

Tighten diesel injection pump bracket

| • |

Tighten 2 bolts ( 18.6 Nm )

|

|

| 15. |

Insert inner diesel injection pump insulation

|

| 16. |

Attach wiring harness for engine management

| • |

Connect wiring harness plug.

|

|

| 17. |

Install outer diesel injection pump insulation

|

| 18. |

Clean sealing surfaces.

|

| 19. |

Install two piece intake manifold

| • |

Tighten bolts, nuts ( 24.5 Nm

)

|

|

| 20. |

Connect wiring harness plug.

|

| 21. |

Install outer oil leak line

| • |

Tighten bolt, banjo bolt ( 14.7

Nm )

|

|

| 22. |

Install charge control sensor

| • |

Tighten bolt ( 9.8 Nm )

|

| • |

Connect wiring harness plug.

|

|

| 23. |

Install exhaust recirculation solenoid valve

| • |

Insert bolts with locking compound

|

| • |

Tighten 2 bolts ( 4.9 Nm )

|

| • |

Connect wiring harness plug.

|

|

| 24. |

Install right rear engine transport shackle

|

|