|

Check diesel fuel injection pump setting (Y 17

DTL, without air conditioning, LHD)

Note: KM-6394 must be used from model year 04 instead of

KM-6169-1 .

Important: On vehicles from model

year 04 with ESP - the steering angle sensor loses its basic

adjustment each time the battery is disconnected. It must be

recalibrated.

|

| 2. |

Disconnect battery

|

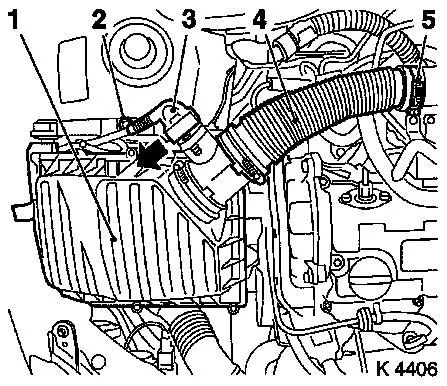

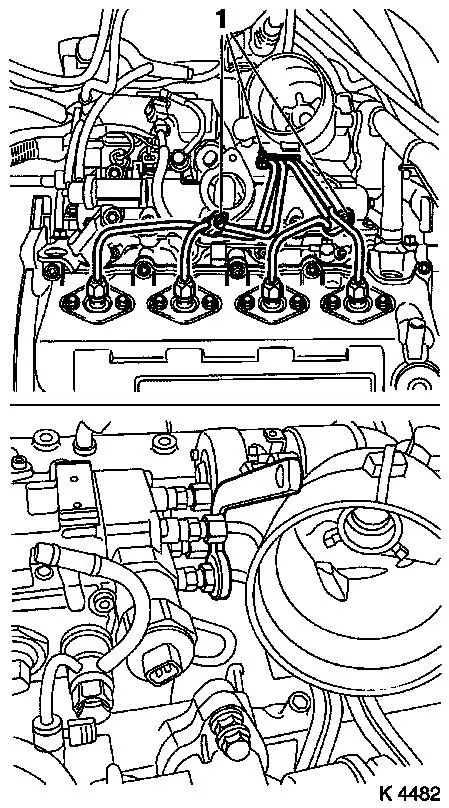

| 3. |

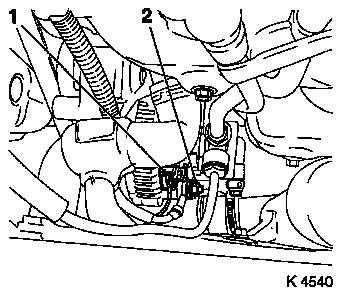

Remove air cleaner housing (1)

| • |

Remove wiring harness plug for hot film mass air flow meter

(3)

| – |

Release in direction of arrow

|

|

| • |

Remove air intake hose (4)

|

|

|

|

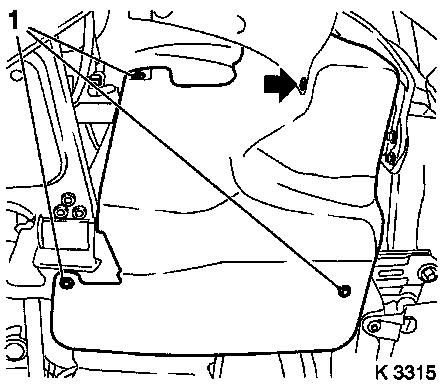

| 4. |

Detach front right wheel

|

| 6. |

Remove front right wheel

|

| 8. |

Remove ribbed V-belt cover

|

|

|

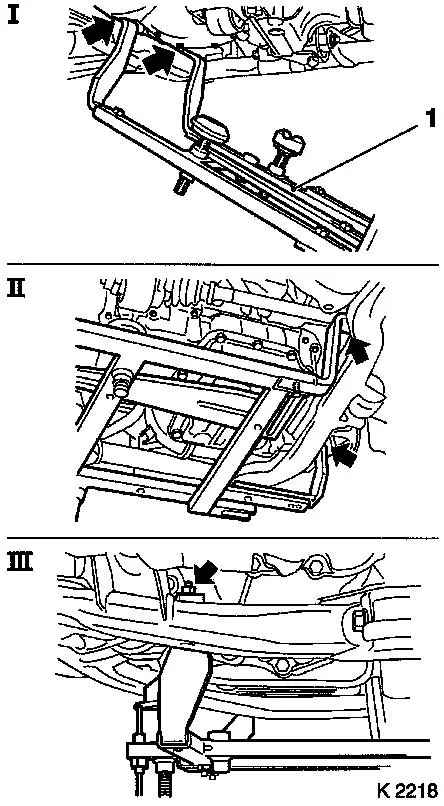

| 9. |

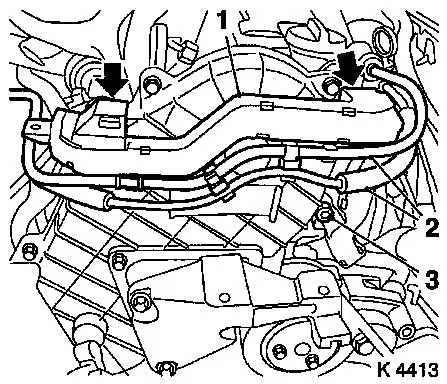

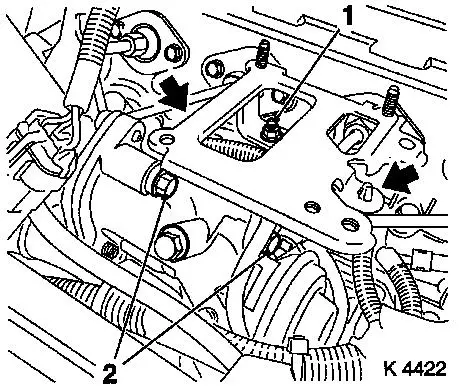

Attach KM-6169 (1)

| • |

Attach KM-6169 at left side of front

axle unit (arrows, fig.I)

Note: Guide pin must be

seated in bore in front axle body

|

| • |

Attach both right holders on the front axle body (arrows,

Illus. II).

Note: Guide pin must be

seated in bore in front axle body (arrow, Fig. III)

|

|

|

|

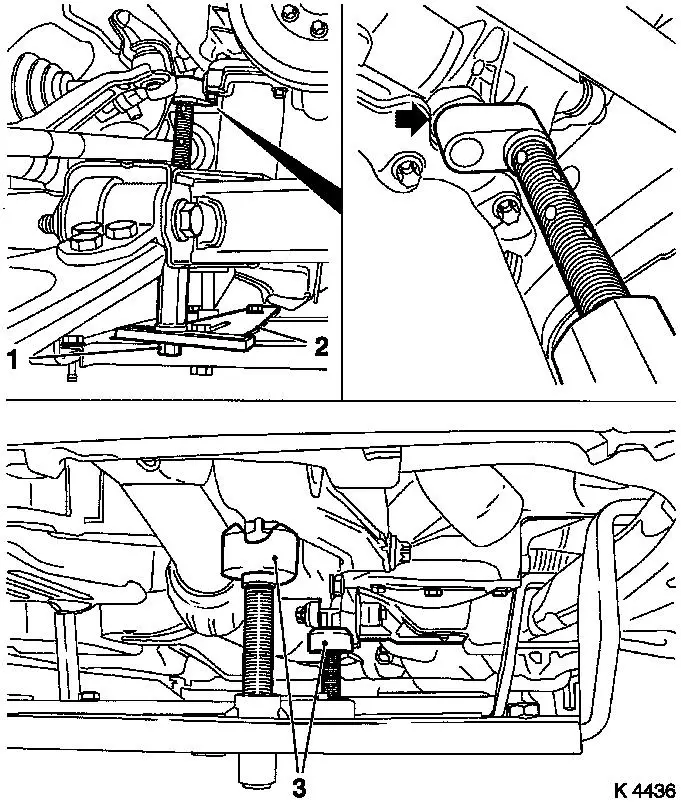

| 10. |

Install support

| • |

Adjust bracket (2) for support

|

|

| 11. |

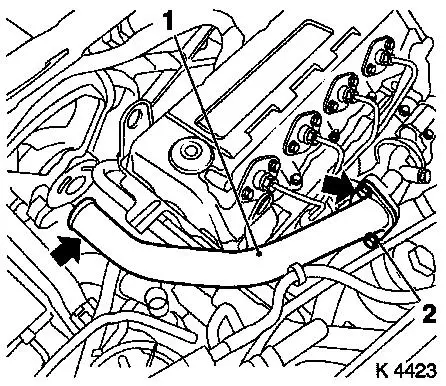

Adjust supports

| • |

Transmission side

Note: Turn spindles

until mounts (3) are positioned at guide journals free of play

|

| • |

Engine timing side

| – |

Insert journal of the support in the bore of the cylinder block

without play (arrow)

|

|

|

|

|

| 13. |

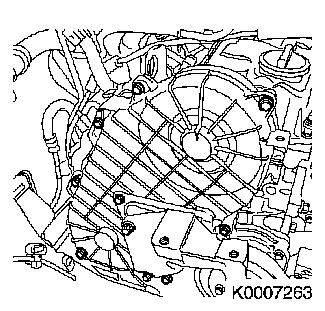

Remove right engine damping block

|

|

|

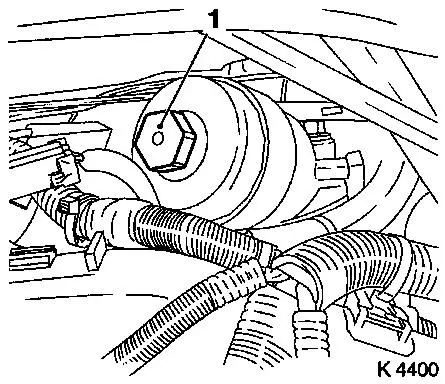

| 14. |

Detach alternator wiring harness

| • |

Disconnect wiring harness plug (1)

|

|

|

|

| 15. |

Remove vacuum pump vacuum lines

| • |

Exhaust gas recirculation solenoid valve

|

|

| 16. |

Remove wiring trough

| • |

Unclip vacuum lines (2)

|

| • |

Unclip wiring trough (1)

|

|

|

|

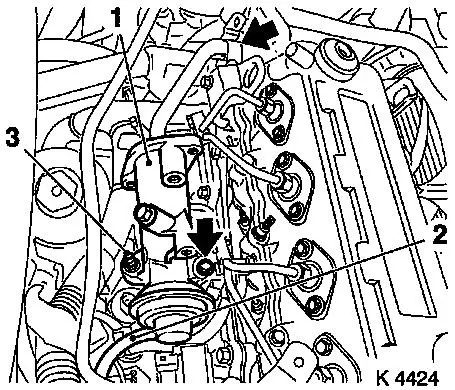

| 17. |

Loosen upper part of toothed belt cover

| • |

Remove 8 bolts

Note: Note dissimilar

bolt lengths

|

|

|

|

| 18. |

Detach right engine bracket

| • |

Remove right engine bracket, right engine bracket adapter,

upper part of toothed belt cover

|

|

|

|

| 19. |

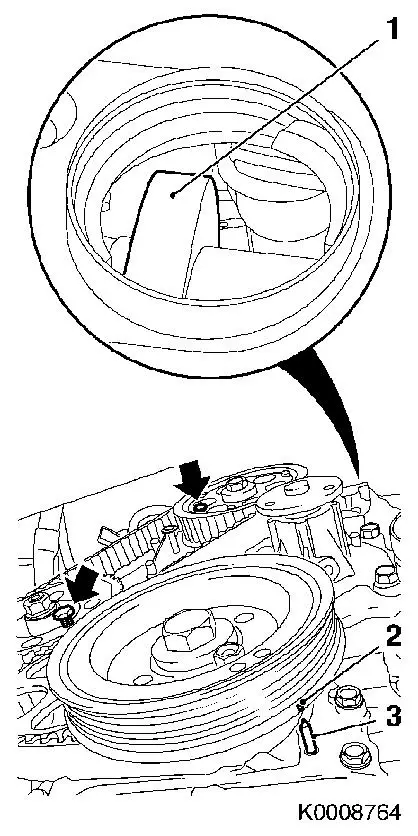

Set no.1 cylinder to TDC

| • |

Rotate crankshaft evenly until torsional vibration damper (2)

mark is flush with pin (3) on oil pump cover. No.1 cylinder exhaust

camshaft (1) must be on top.

|

| • |

Screw in the TDC fixing bolts (arrows)

| – |

Drive gear injection pumps (M8)

|

|

| • |

Unscrew TDC-fixing bolts

|

|

|

|

| 20. |

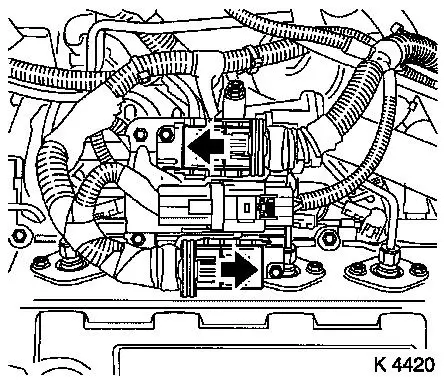

Remove wiring harness plug for engine control unit

| • |

3 off

| – |

Release 2 wiring harness plugs in direction of arrow

|

|

|

|

|

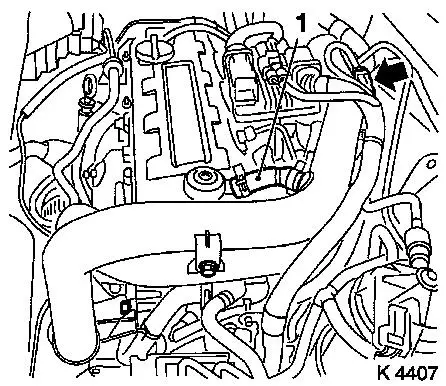

| 21. |

Remove air intake pipe

| • |

Remove vent hose (1)

| – |

From cylinder head cover

|

|

| • |

Unclip wiring harness (arrow)

|

|

|

|

| 22. |

Remove charge air hose

| • |

From turbocharger, centre charge air pipe

|

|

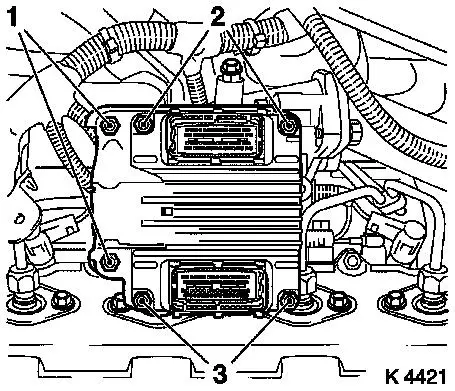

| 23. |

Remove engine control unit

| • |

Unclip wiring harness for engine management

|

| • |

Remove wiring harness plug bracket

|

| • |

Unscrew 2 bolts (2), 2 nuts (3)

|

|

|

|

| 24. |

Remove engine control unit bracket

| • |

Unscrew 2 bolts (2), nut (1)

|

| • |

Unclip wiring harness (arrows)

|

|

|

|

| 25. |

Detach starter/alternator wiring harness bracket

| • |

From exhaust recirculation valve

|

|

| 26. |

Remove centre charge air pipe (1)

| • |

Unscrew studs (2), 2 bolts (arrows)

|

|

|

|

| 27. |

Remove exhaust recirculation valve (1)

| • |

Remove exhaust recirculation pipe

|

| • |

Unscrew studs (3), 2 bolts (arrows)

|

|

|

|

| 28. |

Remove oil filter insert

| • |

Place collecting basin underneath.

|

| • |

Unscrew oil filter housing cover (1)

|

|

|

|

| 29. |

Detach oil filter housing cover return hose

| • |

From oil filter housing

|

|

| 30. |

Detach injection line spacers (1)

Note: Mark spacer

positions

|

| 31. |

Remove injection lines

|

|

|

| 32. |

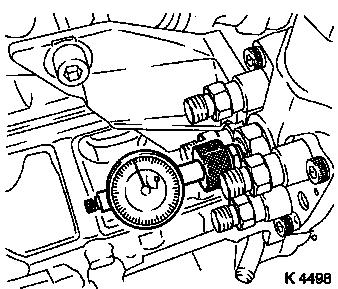

Attach KM-798

| • |

Turn crankshaft in direction of engine rotation to 45°

before no.1 cylinder TDC

| – |

At toothed belt drive gear bolt

|

|

| • |

Remove central bleeder screw

|

| • |

Install KM-798 under pre-tension

|

| • |

Determine BDC position of injection pump plunger by turning

crankshaft back and forth

Note: Dial gauge needle

must not move

|

|

|

|

| 33. |

Check start of feed

| • |

Turn crankshaft to 1st Cylinder TDC

Note: Mark on oil pump

cover must align with mark on torsional vibration damper.

|

Important: If test value is not

achieved, diesel injection pump setting must be corrected - see

operation "Adjusting diesel fuel injection pump".

|

| • |

Read test value

| – |

Test value: 0.28 – 0.38 mm

|

|

|

| 34. |

Remove KM-798

| • |

Tighten central bleeder screw ( 23.5

Nm )

|

|

| 35. |

Install injection lines

| • |

Caution! Injection lines must be installed without tension.

Hand-tighten at injector nozzles and injection pump.

|

| • |

Tighten union nuts ( 22.5 Nm

)

|

|

| 36. |

Install injection line spacers

Note: Pay attention to

spacer positions

|

| 37. |

Attach oil filter housing return hose

|

| 38. |

Install oil filter insert

| • |

Tighten oil filter housing cover ( 23.5

Nm )

|

|

| 39. |

Install exhaust recirculation valve

| • |

Clean sealing surfaces.

|

| • |

Insert exhaust recirculation valve

| – |

Tighten studs, 2 bolts ( 24.5 Nm

)

|

|

| • |

Attach exhaust gas recirculation pipe

| – |

Tighten 2 bolts ( 28.4 Nm )

|

|

|

| 40. |

Install centre charge air pipe

|

| 41. |

Attach starter/alternator wiring harness bracket

|

| 42. |

Install engine control unit bracket

|

| 43. |

Install engine control unit

| • |

Install engine control unit

| – |

Tighten 2 bolts, 2 nuts ( 5.9 Nm

.)

|

|

| • |

Install wiring harness plug bracket

|

|

| 44. |

Install air intake pipe

| • |

Attach engine vent hose

|

|

| 45. |

Attach charge air hose.

|

| 46. |

Connect wiring harness plug for engine control unit

| • |

Connect wiring harness plug.

|

|

| 47. |

Attach right engine bracket

| • |

Insert lower bolt

| – |

Into right engine bracket and right engine bracket adapter

|

|

| • |

Insert right engine bracket, right engine bracket adapter,

upper part of toothed belt cover

|

| • |

Tighten 3 bolts( 40 Nm )

|

|

| 48. |

Fasten upper part of toothed belt cover

| • |

Tighten bolts ( 9.8 Nm )

Note: Note dissimilar

bolt lengths

|

|

| 49. |

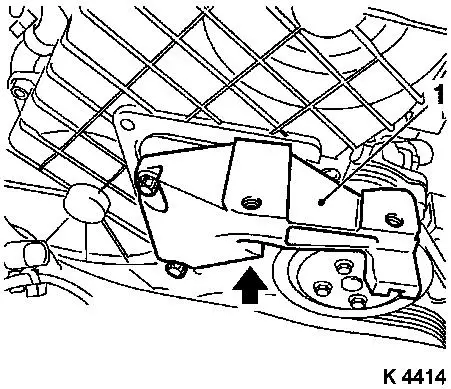

Install right engine damping block

| • |

To side member

| – |

Tighten bolts ( 40 Nm )

|

|

| • |

On engine bracket

| – |

Tighten bolts ( 60 Nm + 30° +

15° )

|

|

|

| 51. |

Attach alternator wiring harness

| • |

Connect wiring harness plug.

|

|

| 52. |

Attach vacuum pump vacuum lines

| • |

Route lines and clip in

|

| • |

Tighten union nut ( 18 Nm )

|

|

| 53. |

Install air cleaner housing

| • |

Fasten air intake hose.

|

| • |

Connect wiring harness plug to hot film mass air flow meter

|

|

| 57. |

Install ribbed V-belt cover

|

| 59. |

Install right front wheel

|

| 61. |

Fasten right front wheel

| • |

Tighten bolts ( 110 Nm )

|

|

| 62. |

Check and correct engine oil level

| • |

Observe specified engine oil quantity

|

| • |

Start engine and allow to run until oil pressure telltale

extinguishes.

|

| • |

Check engine oil level, if necessary correct.

|

|

| 64. |

Calibrate steering angle sensor

| • |

Switch on ignition

Note: Rotate the

steering wheel one time from its right-hand to its left-hand

stop.

|

|

| 65. |

Program volatile memories

|

|