|

Engine Pressure Loss, Check - Diesel Engine

Remove Remove

| 1. |

Condition: engine must be at operating temperature (min. oil

temperature 80° )

|

| 3. |

Disconnect battery

| • |

Ground cable from ground terminal

|

|

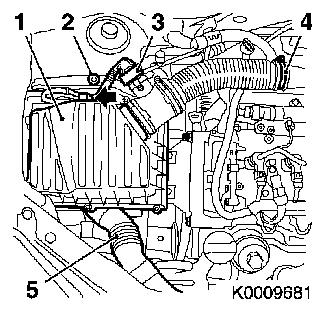

| 5. |

Remove air cleaner housing (1)

| • |

Detach wiring harness of mass air flow meter (3)

| – |

Disconnect wiring harness plug

|

|

| • |

Detach front intake hose (5)

|

|

|

|

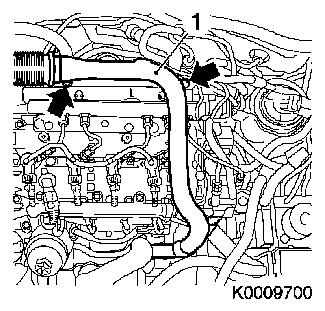

| 6. |

Remove air intake pipe (1)

| • |

Unscrew 2 bolts (arrows)

|

| • |

Unclip fuel line from bracket

|

| • |

Detach engine vent hose

|

|

|

|

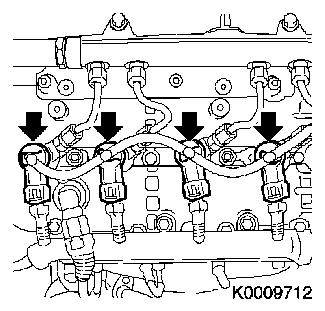

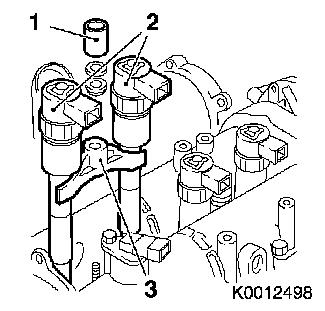

| 7. |

Detach oil leak line

Important: Seal the leak oil line

connection to the injector with closure cap from kit (catalogue

number 45 06 154).

|

| • |

Fit 4 retaining clamps (arrows). Remove oil leak line.

Note: The retaining

clamps will be ruined upon removal (overexpansion).

|

|

|

|

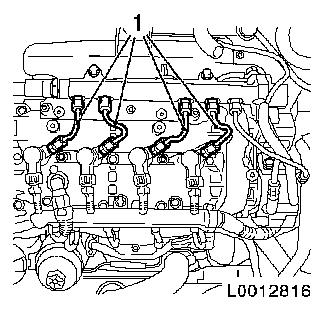

| 8. |

Detach 4 high pressure lines from accumulator to injectors

Important: Seal the connection of

the oil leak line to the injector and accumulator as well as the

high pressure lines with closure caps from the kit (catalogue

number 45 06 154)

|

| • |

Unscrew 8 union nuts (1)

|

|

|

|

| 9. |

Detach wiring harness of injectors

| • |

Detach wiring trough from camshaft housing

Note: Be careful of the

ground cable

|

| • |

Disconnect 4 wiring harness plugs from injectors

|

| • |

Disconnect camshaft sensor wiring harness plug

|

|

| 10. |

Remove 4x injector (2)

Note: The injectors can

only be removed in pairs with the bracket (3) (1st and 2nd cylinder

and 3rd and 4th cylinder)

Important: Seal injector at front

with closure cap from kit (catalogue number 45 06 154)

|

| • |

Unscrew 2 nuts (1)

|

|

|

|

| 11. |

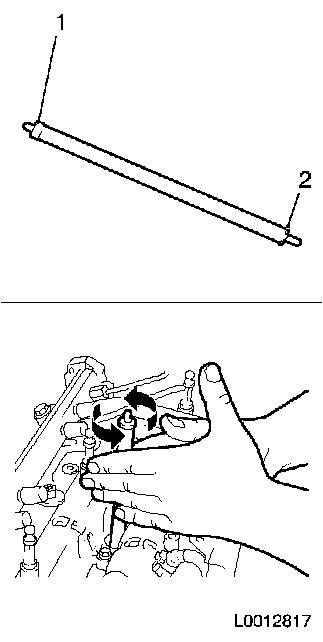

Clean 4 injector seats with EN-47632

| • |

Loosen dirt with brush side (1)

|

| • |

Remove dirt with sponge side (2)

|

|

|

|

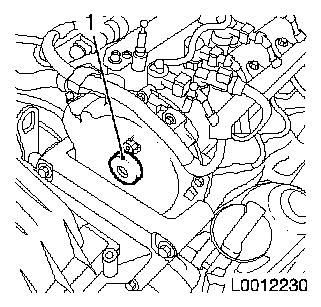

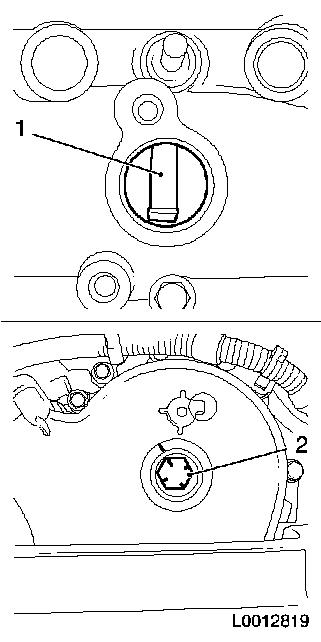

| 12. |

Unscrew timing case closure bolt (1)

|

|

|

| 13. |

Remove camshaft sensor

|

|

|

| 14. |

Set engine to 1st cylinder TDC

| • |

Turn the crankshaft in the direction of engine rotation at the

bolt of the ribbed V-belt drive disc flange until the rear edge of

the elevation for the camshaft sensor aligns with the front edge of

the camshaft sensor installation opening (1)

|

| • |

Affix a guide mark on the timing case and 4 on the camshaft

drive gear bolt (2)

|

|

|

|

| 15. |

Install camshaft sensor

|

| 16. |

Remove coolant compensation tank cap

|

| 17. |

Remove oil filler port closure cap

|

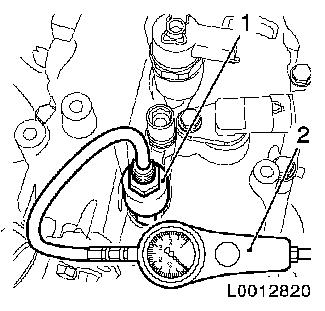

| 19. |

Calibrate pressure loss gauge

|

| 20. |

Engage 4th gear; apply handbrake

|

| 21. |

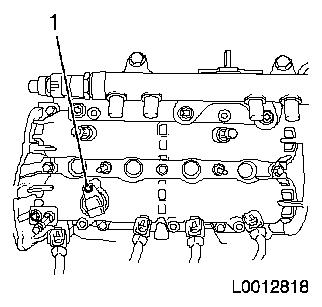

Install EN-46782 (1) with adapter

EN-46783 (2) in conjunction with 2nd

cylinder injector in 1st cylinder

|

| 22. |

Attach pressure loss gauge to adapter EN-46783

|

|

|

| 23. |

Check 1st cylinder pressure loss

|

| 24. |

Remove EN-46782 with adapter EN-46783

|

| 25. |

Install EN-46482 with adapter EN-46783 in 3rd cylinder

| • |

Install EN-46482 with adapter EN-46783 in conjunction with 4th cylinder

injector

|

|

| 26. |

Put vehicle into neutral

|

| 29. |

Check 3rd cylinder pressure loss

|

| 30. |

Remove EN-46782 with adapter EN-46783

|

| 31. |

Install EN-46482 in 4th cylinder

| • |

Install EN-46482 in conjunction with

3rd cylinder injector

|

|

| 32. |

Put vehicle into neutral

|

| 35. |

Check 4th cylinder pressure loss

|

| 37. |

Install EN-46482 in 2nd cylinder

| • |

Install EN-46482 in conjunction with

1st cylinder injector

|

|

| 38. |

Put vehicle into neutral

|

| 41. |

Check 2nd cylinder pressure loss

|

| 43. |

Close coolant compensation tank cap

|

Install

Install

| 44. |

Fit oil filler port closure cap

|

| 46. |

Fasten timing case closure bolt

|

| 47. |

Insert gasket in injector shaft 4x

|

| 48. |

Install 4 injectors

Note: Injectors can

only be installed in pairs (1st and 2nd cylinder / 3rd and 4th

cylinder)

|

| 49. |

Attach wiring harness of injectors

| • |

Connect 4 injector wiring harness plugs

|

| • |

Connect camshaft sensor wiring harness plug

|

| • |

Attach wiring trough to camshaft housing

Note: Be careful of the

ground cable.

|

|

| 50. |

Attach 4 high pressure lines from accumulator to injectors

| • |

Tighten 8 union nuts 24 Nm

|

|

| 52. |

Install air intake manifold

| • |

Attach engine vent hose

|

| • |

Clip fuel line into bracket

|

| • |

Clip in wiring harness (2x)

|

|

| 53. |

Install air cleaner housing

| • |

Attach wiring harness of mass air flow meter

| – |

Connect wiring harness plug

|

|

|

| 54. |

Install engine cover.

|

| 55. |

Connect battery

| • |

Ground cable to ground terminal

|

|

| 56. |

Program volatile memories

|

|