| –

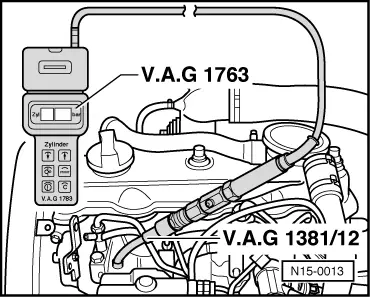

| Screw the -V.A.G 1381/12- adapter in the place of the glow plugs. |

| –

| Check the compression using the -V.A.G 1763- compressograph. |

Note! | Use of the checking apparatus ⇒ Instructions for use. |

| –

| Run the starter motor until the checking apparatus no longer indicates an increase in pressure. |

| Admissible difference between the cylinders: 5 bar |

| –

| Fit the glow plugs with the tool -U-40082-. |

Note! | On separating the connectors to the injection pump, faults are memorised. Therefore, it is necessary to consult the fault memory and delete if needed. |

|

|

|

Note!

Note! Note!

Note!

Note!

Note! Note!

Note!