LR3/Disco 3

Unless stated in a specific repair procedure, self-locking bolts and screws i.e. nylon patched or trilobular thread can be re-

used provided that resistance is felt when the locking portion enters the female thread.

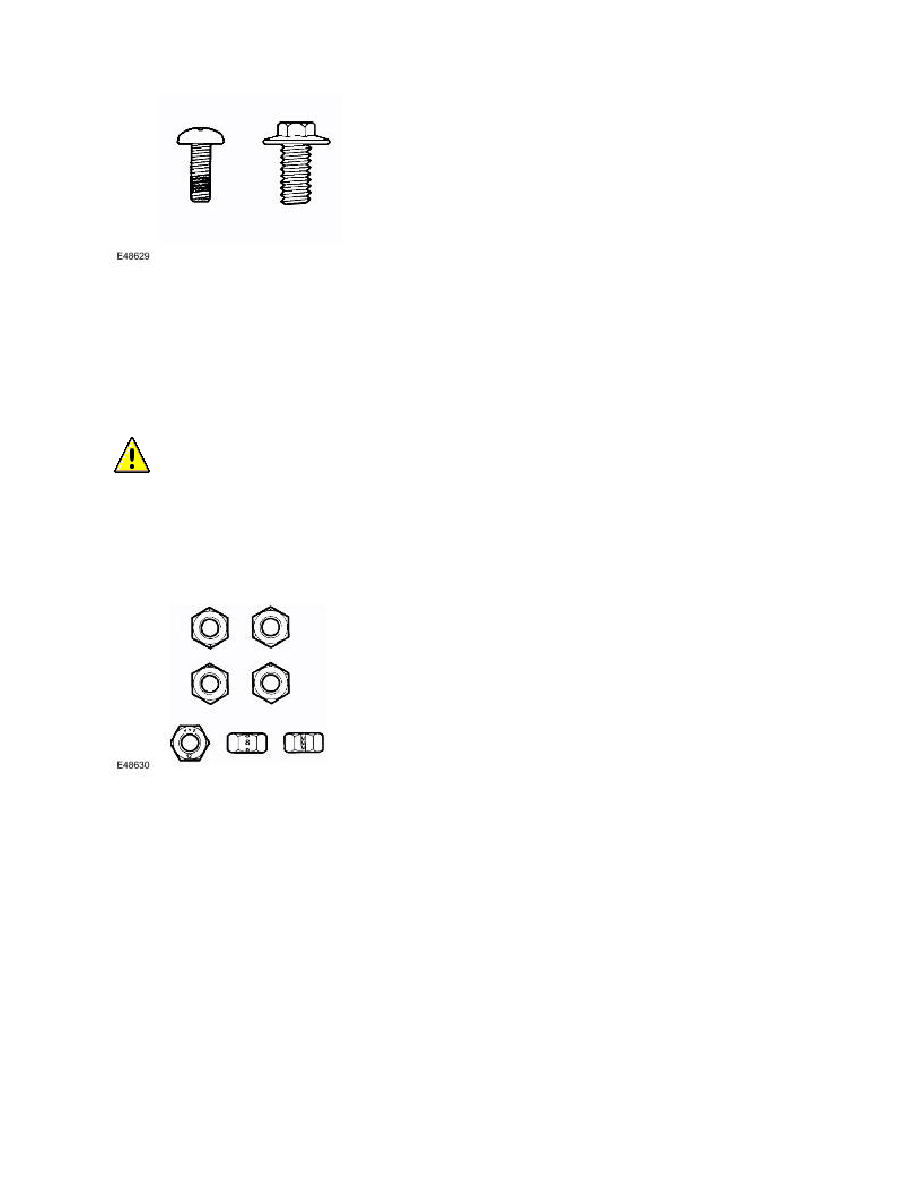

Nylon patched bolts and screws have a locking agent either applied to, or inserted in the threaded portion. They are

identified by the presence of a colored section of thread extending approximately 180 ° around the thread or by a colored

plug inserted into the bolt.

Trilobular bolts have a special thread form which creates a slight interference with the thread of the hole or nut into which

it is screwed.

Trilobular bolts should not be used as a substitute for patched bolts.

Nut identification

A nut with an ISO metric thread is marked on one face or one of the hexagonal flats with the strength grade symbol 8, 12,

14. Some nuts with the strength grade 4, 5 or 6 are also marked and some have the metric symbol M on the hexagonal

flat opposite the strength grade marking.

A clock face system is sometimes used as an alternative method of indicating the strength grade. The external chamfers

or a face of the nut is marked in a position relative to the appropriate hour mark on a clock face to indicate the strength

grade.

A dot is used to locate the 12 o'clock position and a dash to indicate the strength grade. If the grade is above 12, two dots

identify the 12 o'clock position.

When tightening a slotted or castellated nut, never loosen it to insert a split pin except where specified as part of an

adjustment procedure. If difficulty is experienced in correctly positioning the slot, alternative washers or nuts should be

selected.

Where a nut is tightened to adjust or maintain bearing pre-load, the tightening procedure must be adhered to.

Self-locking nuts

CAUTION: Do Not re-use self-locking fasteners in critical locations e.g. drive plates/flywheel or engine

bearings. Do not fit non self-locking fasteners where a self-locking fastener is specified.