LR3/Disco 3

Correct orientation of cooling system hoses is important to ensure that hoses do not become fatigued or damaged

through contact with adjacent components.

Where orientation marks are provided on the hose and corresponding component, the marks must be aligned when the

hose is fitted. Hoses must be fitted fully on to their connection points, usually a moulded form on a pipe provides a

positive indicator.

Hose clips

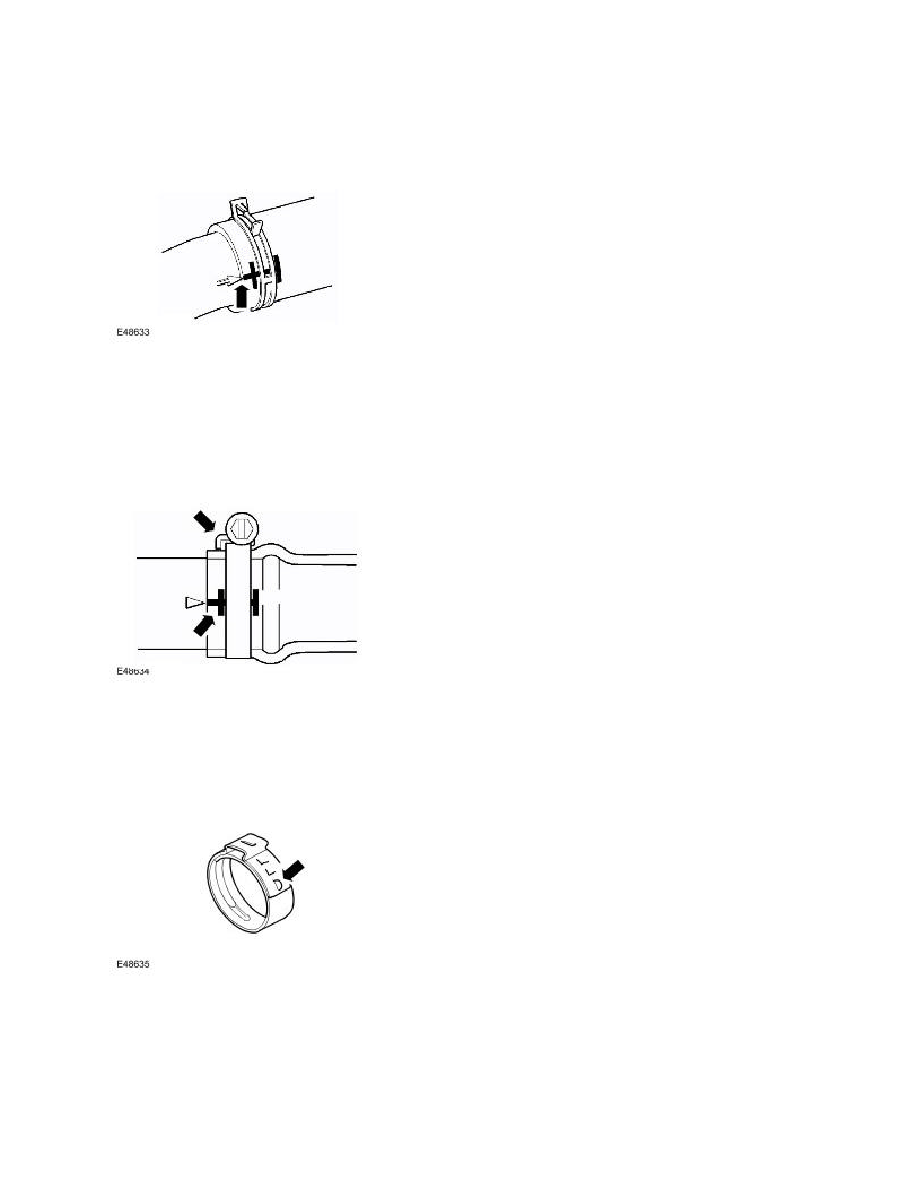

Markings are usually provided on the hose to indicate the correct clip position. If no markings are provided, position the

clip directly behind the retaining lip at the end of the stub pipe. Worm drive clips should be orientated with the crimped

side of the drive housing facing towards the end of the hose or the hose may become pinched between the clip and the

stub pipe retaining lip. Unless otherwise stated, worm drive clips should be tightened to 3 Nm (2 lb-ft). Ensure that hose

clips do not foul adjacent components.

Oetiker clips may be removed by bending the tag (arrowed) and releasing the free end of the clip. Clips must not be re-

used. When fitting new clips, ensure clip is positioned on hose before tightening and ensure that when clip is tightened,

the tag is located in the longitudinal slot in the free end of the clip (arrowed in illustration).

'Quick-fit' connections are also installed to certain hoses/pipes. Inspect 'quick-fit' connections for damage, prior to

connection. Replace if damaged. After engagement of 'quick-fit' connections, perform a 'tug' test to make sure connection

is securely fitted.